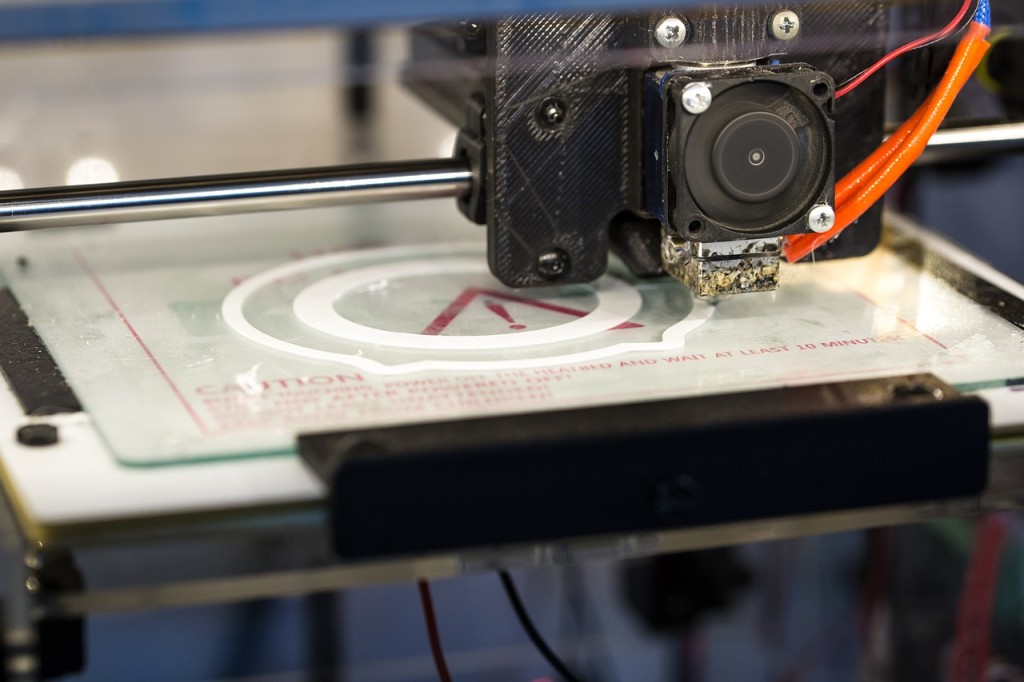

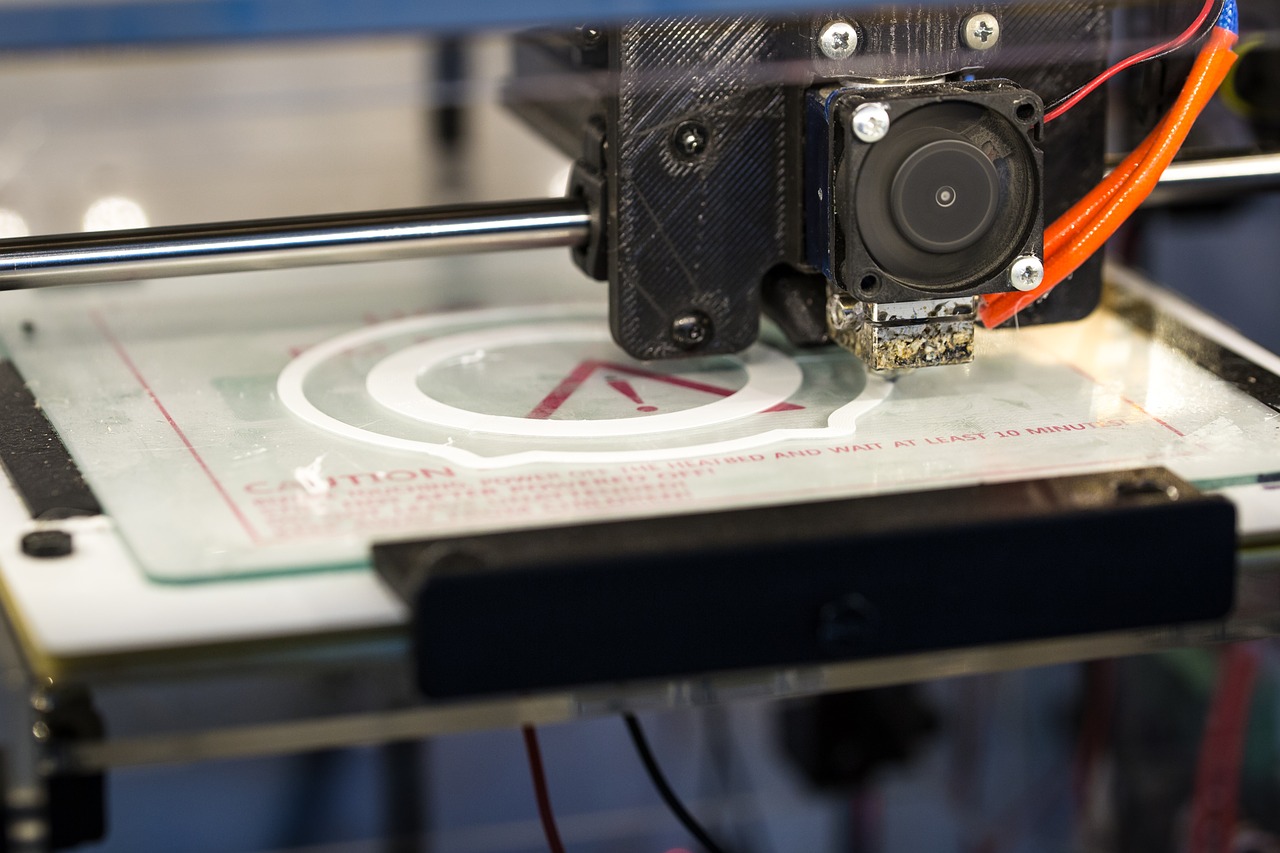

The 3D printings technology have been in use for more than 30 years but this revolutionary technology has been gaining prominence recently. In the present times, with the technology progression, a lot has changed and the 3D printers are gaining popularity. The 3D printing is also popularly known as additive manufacturing. It turns the 3D models into solid objects by building them in layers. Over the years the 3D printing technology has improved and evolved into a next generation technology that is extensively used for creating prototypes of intricate objects. The 3D printing includes a wide range of the additive manufacturing technologies. With the help of the technology, you can create anything you envision.

Producing prototypes via this 3D printing method offers many advantages over the traditional manufacturing techniques. There are endless possibilities of 3D printing and seeing various advantages different industries are adopting the 3D printing technology far and wide.

3D printing technology continues to develop and has started to build its way to in several industries, for instance, health care, dental, entertainment, aerospace, education, and automotive industries to create prototypes of the varied products. Additionally, 3d printing is also widely used in the furniture manufacturing, toys manufacturing, as well in the fashion industry.

Below are discussed a few potential benefits of the 3D Printing:

- Although, the initial cost of setting the 3D printing is high. But the 3D printing offers affordable options to create parts through the additive manufacturing at much cheaper prices than the traditional manufacturing procedure.

- Many companies are utilizing the 3D printing technology for cheap manufacturing and replacing some of their traditional manufacturing process for cost saving. As the traditional ways of prototyping production methods are expensive.

- It helps to mitigate the risk as when creating a new project. Before investing in the expensive molding tool the manufacturer can verify the design and make the changes in the existing mold using the technology. By this way, it will be easy to create an accurate prototype as required.

- With the help of the 3D printing technology, better quality and perfect prototypes can be created.

- Unlike the traditional industrial manufacturing procedure, the 3D printing utilizes fewer tools and applications of which most industrial manufacturers are taking advantage.

- In comparison to the traditional methods of manufacturing 3D printing takes less time in creating prototypes designs as well as the end product.

- The prototypes created by the 3D printing technology are not only made quickly but also appear very close to the original product.

- With the help of the 3D printing, it is possible to customize the design by making adjustments in any part of the prototype without any complications. 3D printing makes it achievable to create intricate structures and shapes that were not practicable before.

- There is very less wastage of material and as well as use less energy for the reason, 3D printing is also considered as an environmentally friendly and sustainable technology for the future.

It is a technologically advanced world and the organizations look forward to updating their technologies to stay ahead. 3D printing, being an expensive investment is adopted by the organizations. There are endless possibilities of creating new and complex prototypes with the aid of the 3D printing technology. By utilizing the 3D printing technology now the manufacturers can print the unique, customized and intricate product designs and the inventors can create products that they envision without any limitation. Moreover, with this powerful technology new customized products and expansion to the new market is possible.

The access to the 3D printing technology has made it popular in countries like Europe, U.S., and India. The 3D printers are used in different fields that include fashion, dentistry, healthcare, and in the high-end engineering industries like automotive, aerospace, specialty components, etc. With the continuous research and development in the field of the technology, it is expected that the 3D printing technology will improve and become much affordable and accessible to every industry.

With the many benefits, the 3D printing brings, the future of the manufacturing might be entering a new phase where it will be possible to manufacture complex products much faster at a significantly low-cost that ever before. However, this technology is still evolving to offer better results and has its own set of shortcoming which cannot be ignored and need to be mitigated. This highly developed technology will prove to be beneficial and help in revolutionizing the process of manufacturing the prototypes and end products in a more efficient manner and help different industry organizations to enhance their productivity and efficiency level to a greater extent with further development and improvement.

![Watch Video Now on xiaohongshu.com [以色列Elevatione perfectio X美容仪 perfectio X 全新仪器黑科技了解下]](https://www.techburgeon.com/wp-content/uploads/2019/07/perfectiox-singapore-150x150.jpg)