Microscopes are crucial instruments in medical research. After all, magnifying an object beyond the cellular level is an important step towards furthering our knowledge of medicine and improving our quality of life.

But at these minute scales, even tiny adjustments can be the difference between a sharp image and a messy blur of unfocused light. This is why modern microscopes rely more on micro drives that automate the process of how a slide is placed on the microscope’s stage.

Modern microscopes no longer depend on manual knob-turning to make adjustments. Higher-end models now use servo drives to transmit commands into fine adjustments that are accurate to the nanometer.

Rotation Translated into Motion

Indeed, modern microscopes rely on plenty of moving parts to guarantee a clearly discernable image. And there are quite a few ways to do this. Previously, most automated microscope stages used lead screws that passed through a lead nut. An induction motor causes the screw to rotate and the nut travels along the threads of the screw, allowing for movement along a straight line.

For the longest time, this was seen as the simplest and cheapest means to translate energy into motion. However, the mechanism suffers from high amounts of wear due to the friction between the screw and the nut. Aside from increasing energy use, the added heat reduces long-term precision and repeatability. Luckily, there’s more than one way to power a high-powered microscope stage.

Linear Motion

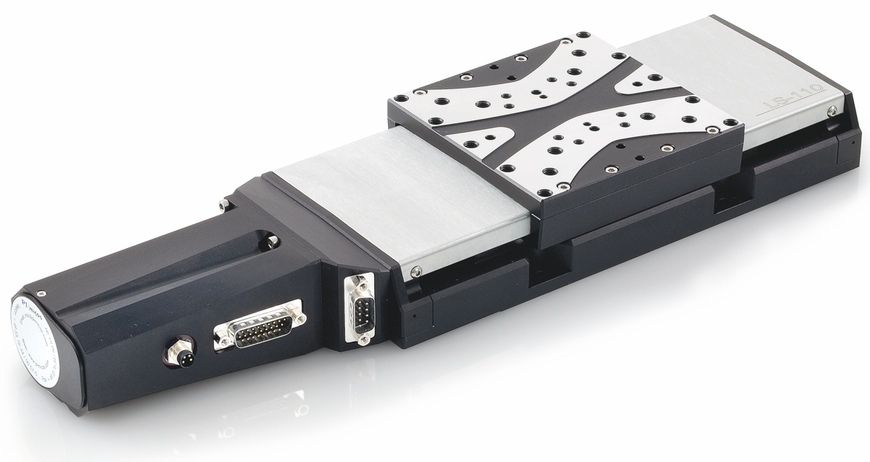

Compared to a system that relies on the rotary mechanics of a screw, linear motor stages provide a more stable platform for clearer imaging. Instead of indirectly inducing motion through a rotary force, this type of linear stage uses electromagnetism to directly move an object along a linear path.

Because the payload is limited to a single dimension, linear motors allow for more direct, precise, and incremental adjustments. Unsurprisingly, this makes them more expensive than their screw-driven counterparts. However, this system also produces less friction—resulting in higher energy efficiency and greater repeatability.

What’s more, there are other related technologies that provide custom linear motors a wider range of motion. XY stages, which use more than one axis, lets an operator tilt the slide for a different angle of view. In addition, air bearing stages increase accuracy by letting the main rotor “float” on a thin film of air. As our knowledge of linear motion continues to advance, you can expect more developments to improve this technology in the future.

In spite of the development of linear motion technology, screw-driven microscope stages endure as valuable positioning tools. Overall, they offer laboratories and operators cost-efficient means to upgrade their microscopes.

It doesn’t mean that the smoother and more accurate linear motors are prohibitively expensive. As a matter of fact, improved manufacturing methods and increasing demand has helped push its prices lower—if still more expensive than screw-based drives. But when you factor in maintenance costs, a linear motor system can be less expensive over traditional screw alternatives. This is especially true if you’re expecting to get some heavy duty use out of your microscope.

But this is just a small glimpse into the cutting-edge world of motion solutions. If you’re still having a hard time deciding, you can also get some expert opinions from motion experts to know what best suits your needs.

In spite of the development of linear motion technology, screw-driven microscope stages endure as valuable positioning tools. Overall, they offer laboratories and operators cost-efficient means to upgrade their microscopes.

It doesn’t mean that the smoother and more accurate linear motors are prohibitively expensive. As a matter of fact, improved manufacturing methods and increasing demand has helped push its prices lower—if still more expensive than screw-based drives. But when you factor in maintenance costs, a linear motor system can be less expensive over traditional screw alternatives. This is especially true if you’re expecting to get some heavy duty use out of your microscope.

But this is just a small glimpse into the cutting-edge world of motion solutions. If you’re still having a hard time deciding, you can also get some expert opinions from motion experts to know what best suits your needs.

![Watch Video Now on xiaohongshu.com [以色列Elevatione perfectio X美容仪 perfectio X 全新仪器黑科技了解下]](https://www.techburgeon.com/wp-content/uploads/2019/07/perfectiox-singapore-150x150.jpg)